One of the most frequent mistakes in rigging is failing to properly inspect and maintain the lifting equipment. Therefore, it is essential for rigging professionals to understand the do’s and don’ts of rigging heavy loads for lifting.

Rigging crews play a pivotal role where heavy equipment needs to be lifted and moved. From construction sites to manufacturing facilities, these crews face unique challenges that require careful consideration. In this blog post, we'll explore the world of rigging, focusing on how the appropriate use of chain and sling hoists can not only safeguard the crew and equipment but also boost efficiency and cut costs. Let's dive in!

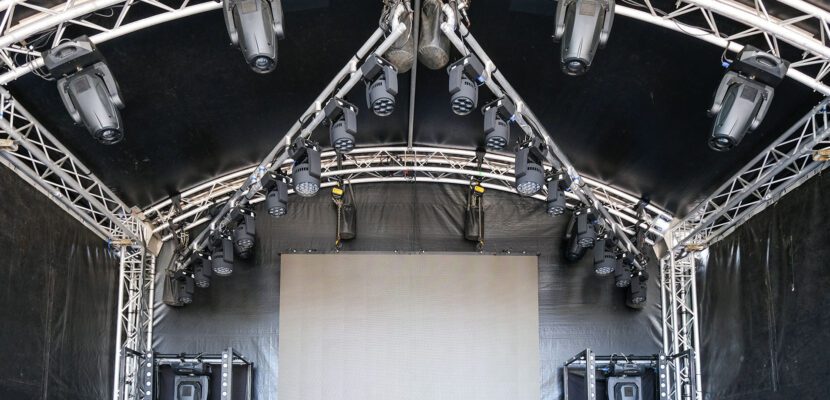

Rigging is a necessary activity in industries such as construction, manufacturing, shipbuilding, and even entertainment. Whether it's lifting steel beams, assembling machinery, or setting up stages for concerts, rigging professionals ensure that heavy objects are moved safely and effectively.

Rigging is a necessary activity in industries such as construction, manufacturing, shipbuilding, and even entertainment. Whether it's lifting steel beams, assembling machinery, or setting up stages for concerts, rigging professionals ensure that heavy objects are moved safely and effectively.

As long as heavy objects need to be lifted, rigging expertise will be in demand and the demand for skilled riggers remains steady across industries. Riggers who stay up-to-date with safety regulations and master the use of advanced equipment, like chain and sling hoists, will find themselves with valuable and sought-after skills.

Riggers are responsible for securing loads, attaching lifting equipment, and ensuring that the entire lifting process is executed seamlessly. Their knowledge of different types of hoists, slings, and chains is crucial for maintaining safety and efficiency.

executed seamlessly. Their knowledge of different types of hoists, slings, and chains is crucial for maintaining safety and efficiency.

A rusty chain or a frayed sling might seem minor, but they can lead to disastrous consequences during a lift. Lifting heavy equipment is inherently risky, making regular inspection and maintenance a critical function. Without the right precautions, there's a potential for dropped loads, damaged equipment, and even injuries or fatalities. This is where proper training and equipment come into play.

Inadequate training and poor communication can lead to rigging failures. Ignoring load limits, improper sling angles, and using damaged equipment are all recipe for disaster. The good news is that these failures are preventable.

The most important rule during rigging and lifting operations is to follow protocols diligently. This includes conducting pre-lift meetings, ensuring everyone is clear about their roles, adhering to load limits, and maintaining constant communication.

OSHA mandates regular hoist testing to ensure that lifting equipment is in optimal working condition. Hoists should be load tested at 125% of their rated capacity and undergo periodic inspections. Adhering to OSHA's requirements not only ensures compliance but also safeguards the crew and equipment.

Mastering the art of rigging is a blend of expertise, attention to detail, and commitment to safety. By understanding the unique challenges rigging crews face, acknowledging the risks, and following best practices—especially when it comes to using chain and sling hoists—these crews can ensure smoother operations, protect their team members, and contribute to the overall success of their projects. See our prior articles on “Proper OSHA Chain and Sling Hoist Testing” and “Chain and Sling Hoist Safety Precautions” for more details on how to keep crews, customers, and equipment safe.

Remember, every lift is an opportunity to prioritize safety and efficiency through proper rigging techniques and equipment usage. For information on cost effective equipment to assist in monitoring chain and sling hoist’s reliability. Visit https://pridetool.com/products/6-ton-hoist-test-stand/ or contact Pride Tool at pride@pridetool.com.

Remember, every lift is an opportunity to prioritize safety and efficiency through proper rigging techniques and equipment usage. For information on cost effective equipment to assist in monitoring chain and sling hoist’s reliability. Visit https://pridetool.com/products/6-ton-hoist-test-stand/ or contact Pride Tool at pride@pridetool.com.

I appreciate you informing us that rigging is necessary in various industries since this ensures that heavy objects are moved safely and effectively by following up-to-date safety regulations. My cousin runs a construction company in Lebanon and it seems like he plans to hire new rigging services to help them out with their upcoming project soon. I’ll keep this in mind while I look for licensed rigging services in Lebanon to recommend to my cousin for their project soon. https://www.sentrysteel.com/rigging/lebanon-tn

So happy you found our article useful. Thank you for letting us know. So many industries never consider providing cost effective and safety concious lifts when dealing with heavy objects.

Claire, amazing to see you have so many family members involve in the construction industry. The links you have provided for the training servicing of the equipment are right on target. Thank you for providing them. Please let us know if you need any hoist test equipment. Pride Tool offers both mobile and stationary models!

So, there are several steel beams I intend to relocate from my backyard. You pointed out that rigging is needed for heavy-duty lifting, right? Okay, let me find a rental company to get the right equipment. https://radiuscraneandrigging.com/rigging-services

Sam, you are on the right track. There are local operators that help with projects to protect both you, your property, and equipment. Thank you for the providing a great resource.

It’s good that you mentioned that rigging is necessary in the construction industry since this helps ensure heavy objects are moved safely and effectively by authorized professionals. My brother runs a construction firm in Springfield, and it seems like he needs to get riggers trained for their upcoming project soon. I’ll keep this in mind while I look for an industrial service in Springfield to hire for the rigging training his workers need. https://www.industrialsplicing.com/product-training-services