In today’s industrial landscape, workplace safety is paramount. Proper testing and inspection of lifting equipment, such as hoists, chains, and slings used in heavy load handling operations, play a critical role in preventing accidents and ensuring the well-being of workers. In this article, we’ll delve into the world of OSHA lifting device testing, exploring the requirements, safety precautions, common problems, and the factors influencing sling safety.

Understanding OSHA Requirements

The Occupational Safety and Health Administration (OSHA) establishes guidelines that govern the use of lifting equipment, including hoists, chains, and slings. OSHA requires thorough testing and inspection of these components to ensure they’re in optimal condition. Lifting device testing is not just a regulatory obligation but a means to safeguard lives. OSHA does indeed require slings to be inspected daily before use.

Daily Sling Inspections: A Must

One of the fundamental aspects of lifting device testing is the daily inspection of slings before use. OSHA mandates that slings must be thoroughly examined for any signs of wear, damage, or deformities. This daily ritual acts as a frontline defense, identifying potential issues that could compromise the safety of lifting operations.

Safety Precautions for Sling Usage

When working with chains and slings, adherence to safety precautions is vital. Workers must be trained to understand the proper methods of handling and attaching slings to loads. Overloading, sudden jerks, and improper angles can all lead to catastrophic failures. Training programs and clear communication protocols are crucial in maintaining a safe working environment.

Common Problems That Halt Sling Usage

Even with proper inspections and precautions, issues may arise that warrant taking a sling out of service. Two common problems include:

-

- Visible Wear and Tear: If a sling displays fraying, cuts, or any visible damage, it must be immediately removed from service. Ignoring such signs can lead to sudden failures during lifting operations.

- Inadequate Load Identification: Each sling has a specific weight capacity. Failure to accurately identify the load’s weight and choosing the appropriate sling can lead to overloading and potential accidents.

Factors Influencing Sling Safety

Sling safety depends on various factors:

-

- Sling Angle: The angle at which the sling is used affects its capacity. Angles significantly deviating from vertical can reduce the sling’s lifting capacity, potentially leading to failure.

- Sling Material and Type: Different slings are designed for specific purposes. Understanding the characteristics of various sling materials (chain, wire rope, synthetic) and configurations (single leg, double leg, multiple leg) is crucial for safe hoisting.

- Environmental Factors: Harsh environments, such as extreme temperatures or exposure to corrosive substances, can compromise sling integrity over time.

Manufacturing Statistics: The Consequences of Improper Testing

The importance of proper hoist testing is evident in manufacturing statistics. Studies show that a significant percentage of chain and sling hoist failures can be traced back to inadequate testing and inspections. These failures not only result in injuries but also cause financial losses for companies due to halted operations, equipment damage, and legal implications.

In the world of lifting operations, the stakes are high, and safety is non-negotiable. OSHA’s regulations regarding lifting devices, hoists, chains, and slings testing exist to ensure that workers are protected, and operations run smoothly. By adhering to the recommended inspection frequencies, practicing safety precautions, addressing common problems, and considering the factors that influence lifting device safety, companies can mitigate the risk of accidents and create a secure working environment.

For more information on OSHA testing requirements or on how you can provide an easy, efficient, accurate, and portable testing solution, visit https://pridetool.com/products/ or contact us today.

Citations

Occupational Safety and Health Administration, Standard Number: 1910.184,

https://www.osha.gov/laws-regs/standardinterpretations/1988-07-19

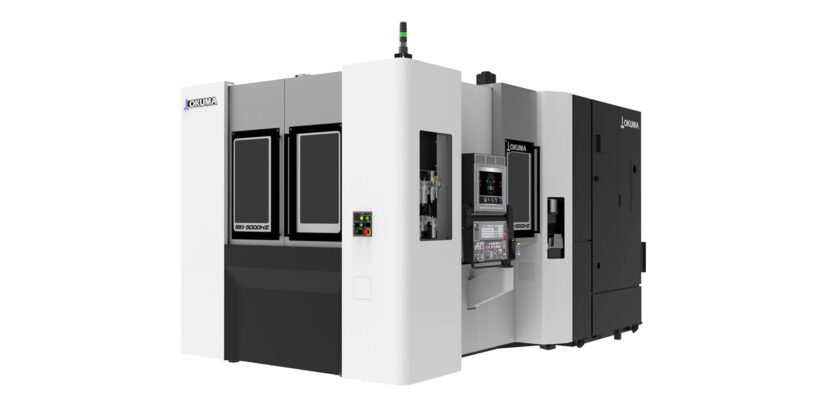

Cincinnati, OH (July 17, 2023) – Pride Tool, a Metal Fabrication and Machine Shop located at 10200 Wayne Avenue in Cincinnati, announced today that it has met the Standards for trust required by the Better Business Bureau and is now a BBB Accredited Business.

Cincinnati, OH (July 17, 2023) – Pride Tool, a Metal Fabrication and Machine Shop located at 10200 Wayne Avenue in Cincinnati, announced today that it has met the Standards for trust required by the Better Business Bureau and is now a BBB Accredited Business.

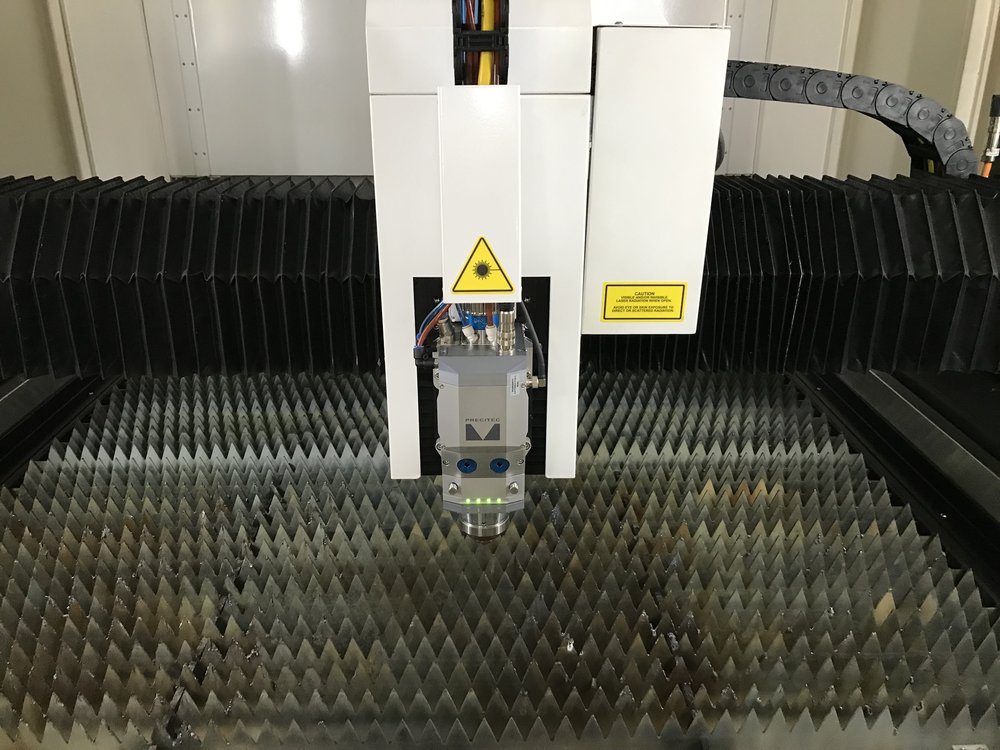

steel, and aluminum. The industries we serve range from automotive to medical, and agricultural to aerospace. Combining this

steel, and aluminum. The industries we serve range from automotive to medical, and agricultural to aerospace. Combining this

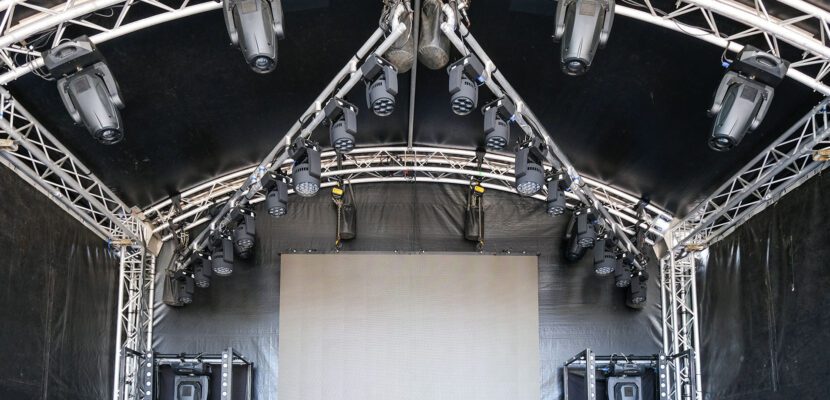

Rigging is a necessary activity in industries such as construction, manufacturing, shipbuilding, and even entertainment. Whether it’s lifting steel beams, assembling machinery, or setting up stages for concerts, rigging professionals ensure that heavy objects are moved safely and effectively.

Rigging is a necessary activity in industries such as construction, manufacturing, shipbuilding, and even entertainment. Whether it’s lifting steel beams, assembling machinery, or setting up stages for concerts, rigging professionals ensure that heavy objects are moved safely and effectively. executed seamlessly. Their knowledge of different types of hoists, slings, and chains is crucial for maintaining safety and efficiency.

executed seamlessly. Their knowledge of different types of hoists, slings, and chains is crucial for maintaining safety and efficiency. Remember, every lift is an opportunity to prioritize safety and efficiency through proper rigging techniques and equipment usage. For information on cost effective equipment to assist in monitoring chain and sling hoist’s reliability. Visit

Remember, every lift is an opportunity to prioritize safety and efficiency through proper rigging techniques and equipment usage. For information on cost effective equipment to assist in monitoring chain and sling hoist’s reliability. Visit

Throughout his longevity with Pride Tool, Steve has continued to utilize his expertise to contribute toward the company’s success, as well as assisting the operations team as needed. As an integral part of the team, Steve dedicates an invaluable amount of knowledge that he uses to continually grow and mentor both new and more junior machinist throughout the shop.

Throughout his longevity with Pride Tool, Steve has continued to utilize his expertise to contribute toward the company’s success, as well as assisting the operations team as needed. As an integral part of the team, Steve dedicates an invaluable amount of knowledge that he uses to continually grow and mentor both new and more junior machinist throughout the shop.

Here are some essential safety precautions to follow:

Here are some essential safety precautions to follow:

Instead of replacing outgoing employees with new employees, help lift employees to grow and fill higher-level positions. This is where empowerment and trust are built. It also encourages team members to be more likely to activate their own professional networks to refer their contacts to join the company.

Instead of replacing outgoing employees with new employees, help lift employees to grow and fill higher-level positions. This is where empowerment and trust are built. It also encourages team members to be more likely to activate their own professional networks to refer their contacts to join the company.