New Talent and Equipment at Pride Tool

Cincinnati’s Leading Machine Shop Is Positioned to Serve the Industry’s Fabrication Needs.

Cincinnati, OH (August 22, 2023); Cincinnati’s leading machine shop, Pride Tool, under the new ownership of Scott Schwarz, has updated equipment and enhanced the staff with additional CNC technicians to better serve the USA Manufacturing Industry.

The acquisition of Pride Tool by Scott Schwarz was completed in the fall 2022. “When I heard about the opportunity to acquire Pride Tool Co. Inc., I was immediately interested,” stated Mr. Schwarz a US Navy Veteran. “This shop was the perfect size and had all the right people and equipment. It felt like my perfect vision of the business I wanted to purchase.”

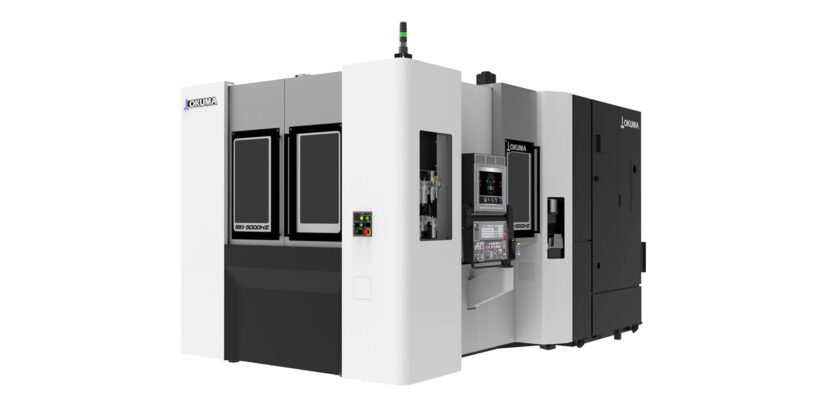

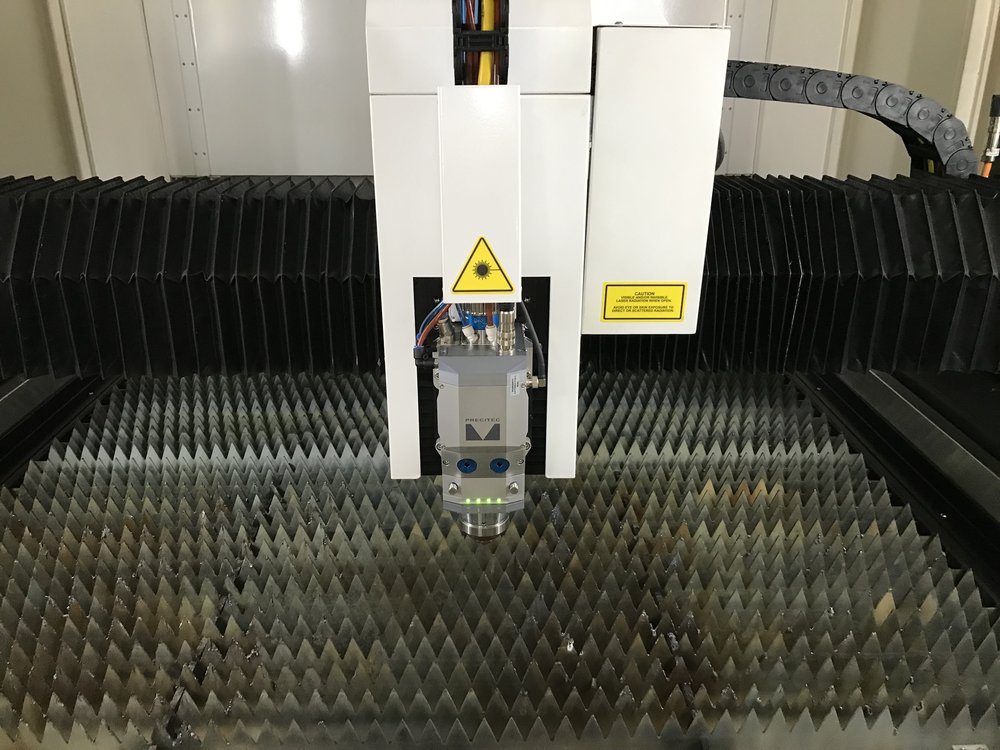

Mr. Schwarz utilized the first quarter of his ownership to analyze the business, assess operational efficiencies, inspect existing equipment and tooling. His research led to investments in new horizontal milling capacity, fiber-laser cutting, press brake forming, and other vital equipment. He also evaluated staffing against similar businesses in the same industry and found that the Pride Tool team was highly. trained, capable and are poised to achieve great things. Additional investments in infrastructure, machine programming, and additional technical specialists will afford the greatest opportunity for Pride Tool’s success. The Cincinnati machine shop supplies B2B metal fabricated and machined precision parts for companies in a multitude of industries, including packaging, automotive, aerospace, medical, military, oil and gas, transportation, and others. Pride Tool also holds a patent for a testing apparatus which is designed into a custom lifting-device testing machine. The Pride Tool Test Stand is used for testing new and modified lifting devices such as chain hoists, lifting winches, and chains and slings. “Our Test Stands are an essential appliance anywhere there is a need to lift heavy objects utilizing hoists and slings. OSHA recommends regular testing of lifting devices,” said Mr. Schwarz. “We build two sizes of our Test Stands: a mobile 6-Ton unit, and our most popular 16-Ton unit. Customers tell us that our Test Stand is one of their best investments. It saves them thousands of dollars in outsourced testing and provides ultimate peace- of-mind knowing the equipment needed to test any device anytime is readily available.”

“I’m very excited to take the lead role at Pride Tool, and with the help of a great team here, we can do great things. With the post-COVID thinking around offshoring changing, we are seeing increased demand every month for machined parts and services. My industry operational excellence experience should prove to be invaluable in taking the company to the next level,” he continued.

Read more about the transformation at pridetool.com.

ABOUT Pride Tool: Founded in 1988, Pride Tool is a leading Machine Shop located in Cincinnati, Ohio that specializes in custom-manufactured and precision-made parts for local and North American manufacturing customers. With a 24,000-square-foot machine shop that houses over 80 specialized machines including laser cutters, welding stations, CNC machining centers, lathes, mills, and ID/OD/surface grinding equipment that employ state-of-the-art CAD/CAM modeling and MasterCam software with internal programming capabilities for CNC Machining and CNC Turning processes. Material expertise includes work with stainless steels, carbon steels, aluminum, brass, bronze, copper, exotics, super alloys, plastics, and all grades of tubing and piping.

Instead of replacing outgoing employees with new employees, help lift employees to grow and fill higher-level positions. This is where empowerment and trust are built. It also encourages team members to be more likely to activate their own professional networks to refer their contacts to join the company.

Instead of replacing outgoing employees with new employees, help lift employees to grow and fill higher-level positions. This is where empowerment and trust are built. It also encourages team members to be more likely to activate their own professional networks to refer their contacts to join the company.

Throughout his longevity with Pride Tool, Steve has continued to utilize his expertise to contribute toward the company’s success, as well as assisting the operations team as needed. As an integral part of the team, Steve dedicates an invaluable amount of knowledge that he uses to continually grow and mentor both new and more junior machinist throughout the shop.

Throughout his longevity with Pride Tool, Steve has continued to utilize his expertise to contribute toward the company’s success, as well as assisting the operations team as needed. As an integral part of the team, Steve dedicates an invaluable amount of knowledge that he uses to continually grow and mentor both new and more junior machinist throughout the shop.

Here are some essential safety precautions to follow:

Here are some essential safety precautions to follow:

Rigging is a necessary activity in industries such as construction, manufacturing, shipbuilding, and even entertainment. Whether it’s lifting steel beams, assembling machinery, or setting up stages for concerts, rigging professionals ensure that heavy objects are moved safely and effectively.

Rigging is a necessary activity in industries such as construction, manufacturing, shipbuilding, and even entertainment. Whether it’s lifting steel beams, assembling machinery, or setting up stages for concerts, rigging professionals ensure that heavy objects are moved safely and effectively. executed seamlessly. Their knowledge of different types of hoists, slings, and chains is crucial for maintaining safety and efficiency.

executed seamlessly. Their knowledge of different types of hoists, slings, and chains is crucial for maintaining safety and efficiency. Remember, every lift is an opportunity to prioritize safety and efficiency through proper rigging techniques and equipment usage. For information on cost effective equipment to assist in monitoring chain and sling hoist’s reliability. Visit

Remember, every lift is an opportunity to prioritize safety and efficiency through proper rigging techniques and equipment usage. For information on cost effective equipment to assist in monitoring chain and sling hoist’s reliability. Visit

steel, and aluminum. The industries we serve range from automotive to medical, and agricultural to aerospace. Combining this

steel, and aluminum. The industries we serve range from automotive to medical, and agricultural to aerospace. Combining this

Cincinnati, OH (July 17, 2023) – Pride Tool, a Metal Fabrication and Machine Shop located at 10200 Wayne Avenue in Cincinnati, announced today that it has met the Standards for trust required by the Better Business Bureau and is now a BBB Accredited Business.

Cincinnati, OH (July 17, 2023) – Pride Tool, a Metal Fabrication and Machine Shop located at 10200 Wayne Avenue in Cincinnati, announced today that it has met the Standards for trust required by the Better Business Bureau and is now a BBB Accredited Business.